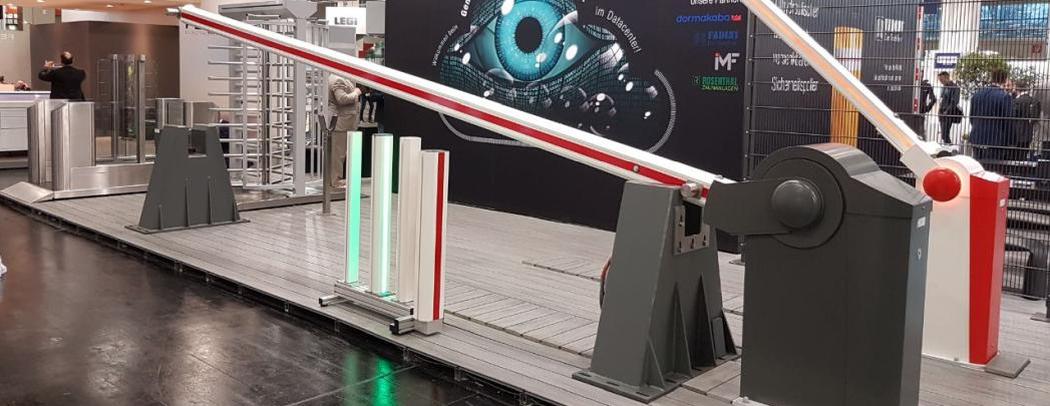

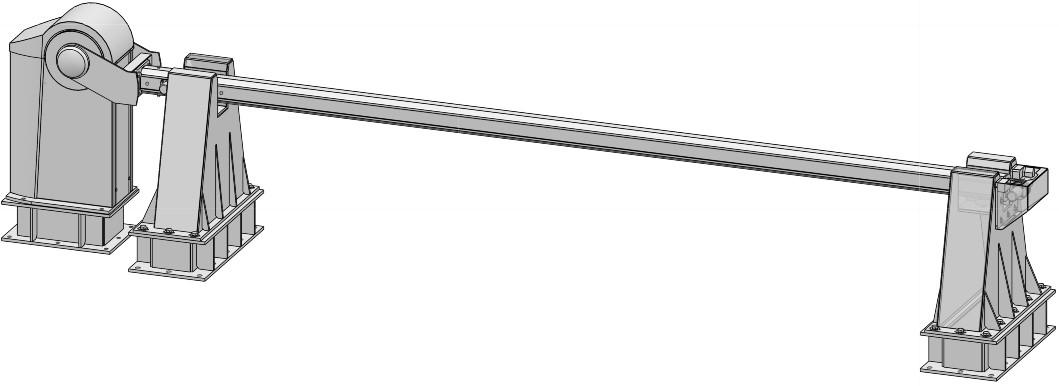

CS-Serie, boom lengths up to 10.000 mm for vehicle traffic

Our heavy duty electro-hydraulic barrier can be custom fitted with an abutment and a bolt lock. Boom in steel or stainless steel with locking grid or lattice correlations possible.

detail of barrier boom lockThese robust and visually appealing hydraulic mechanical barriers are suitable for high security areas such as

detail of barrier boom lockThese robust and visually appealing hydraulic mechanical barriers are suitable for high security areas such as

- airports

- Government Buildings

- Embassies

- military Sites

- Prisons / correctional facilities

- banks

- Data processing centers

- Companies in the energy supply

or other objects which are to be secured by Vehicle barriers.

Scope of application:

Drive-through barrier, for impact loads up to 550 KN. Computational verification and dynamic simulation according to PAS68: 2013 Anti Ram Barrier V / 7500 (N2) /50/90:2.0/3.3 corresponding to 7,5to @ 50Km/h

Design type:

Extremely robust, electrohydraulic barrier system with a maximum opening moment of 10 KNm, consisting of TÜV model tested barrier with barrier housing, barrier boom adapter and barrier boom with integrated circumferential inner steel cable, and 2 abutments of welded steel plates for bolting to the steel concrete foundation.

Basic data:

| Barrier width |

Up to 10 m

|

| Barrier boom |

steel or aluminum profile, dimensions and dimensioning project-specific, with internal circumferential steel cable

|

| Blocking effect |

The impact load of up to 550 KN is initiated as a bending moment into the abutments by means of a circumferential steel cable lying inside the barrier boom. So that the tensile forces can be safely induced into the abutment, 2 rigid locking bolts are located at the ends of the boom. The force effect arises only between the both abutments and the steel cable, so that in the event of a crash the barrier drive is only lightly loaded.

|

| Catching cable |

endless cable, diameter = 20mm, minimum breaking load = 55to

|

| Barrier height |

0.8 to 1m from top of floor

|

| Impact absorption |

> 723KJ

|

| PAS68 |

2013 Classification V / 7500 (N2) /50/902.0/3.3

|

| Opening time |

8 to 15 sec. depending on barrier boom length and weight

|

| Temperature range |

-25 ° C to + 70 ° C

|

| Barrier frame |

stable welded steel construction fully galvanized and powder coated. The base plate of the frame can be screwed directly onto the foundation.

|

| Barrier fork |

stable welded steel construction fully galvanized and powder coated. Main shaft stainless steel, D = 60mm, 2-sided bearing in pedestal housings and sealed deep groove ball bearings

|

| Barrier drive |

Hydraulic cylinder with electric motor-driven hydraulic unit and 5 liter oil tank integrated as a compact unit into the barrier frame.

|

| Drive motor |

three-phase motor, 2.2KW, 400 VAC, 50 Hz

|

| Pump pressure |

adjustable up to 200 bars

|

| Hydraulic cylinder |

D = 80mm, stroke = 300mm, nominal force = 65 KN, both end positions provided with adjustable damping, in addition with lowering brake valve as safety in the event of sudden pressure drop.

|

| Equipment |

Valve unit, filter, hand pump, hydraulic lines as screwed hose connections

|

| Emergency opening |

via manual pump and manual valve actuation

|

| Barrier housing |

Stable construction made of 2mm stainless steel, powder-coated (customer-specific) and bolted to the barrier frame. For maintenance purposes, a simple disassembly is possible.

|

| 2 abutments |

Extremely robust welded construction of 10, 15 and 20mm steel plates, fully galvanized and powder coated. The abutment at the end of the barrier has a locking mechanism that prevents the boom from bending upwards in the event of a crash.

|

| Control |

Programmable logic controller to control the required barrier and interlock functions as well as the optional functions - Control loop detector - Light beam evaluation - safety edge - Key switch - custom signal exchange

|

The independent engineering firm Merkle & Partner has computational proof and dynamic simulation according to PAS68: 2013 Anti Ram Barrier V / 7500 (N2) /50 / 90/2 / 3.3, corresponding to 7,5 to at 50km / h for an IMF crash barrier carried out.

The barrier system of the CS series was designed as a passage barrier for impact loads up to 500 KN.